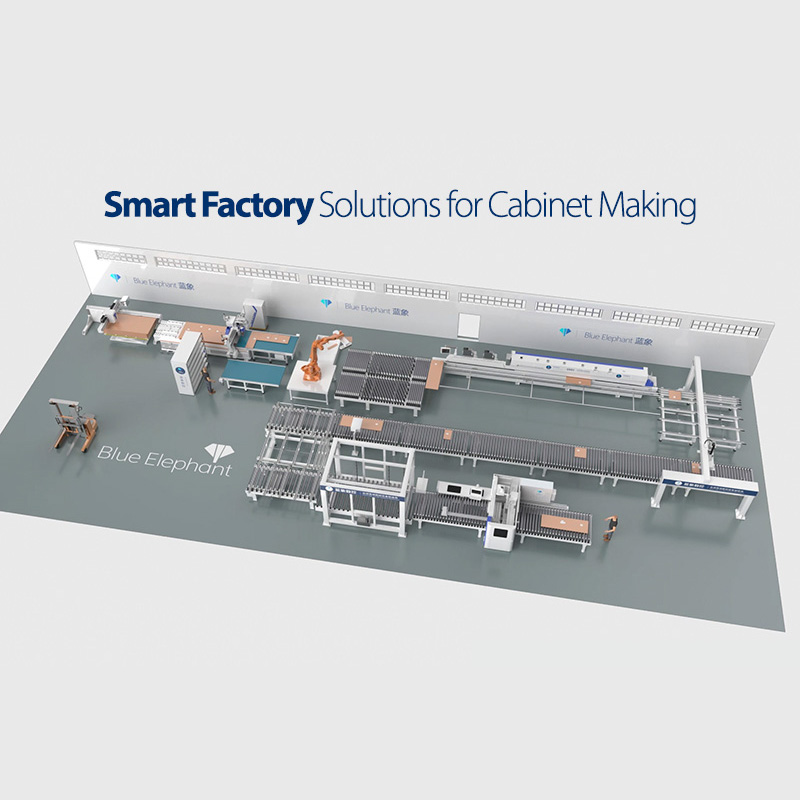

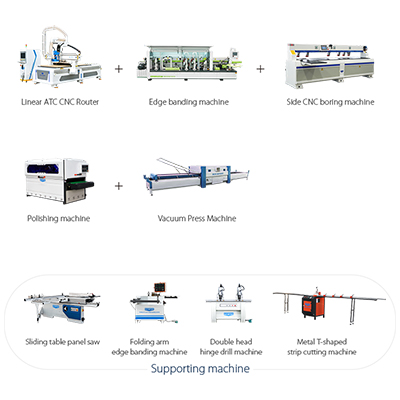

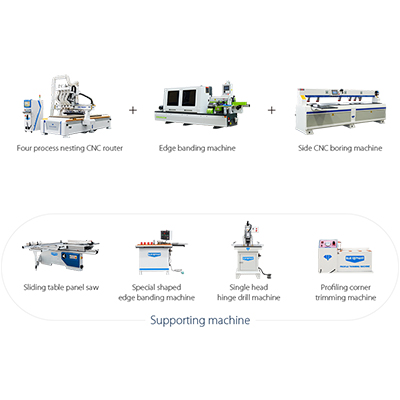

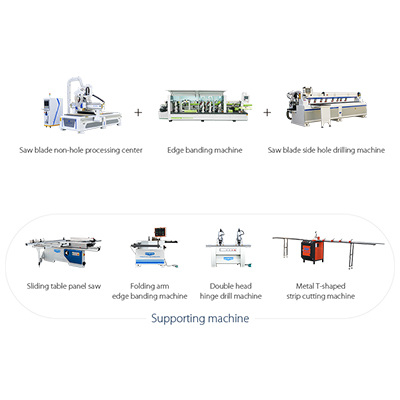

Upgraded Panel Furniture Production Line for Sale

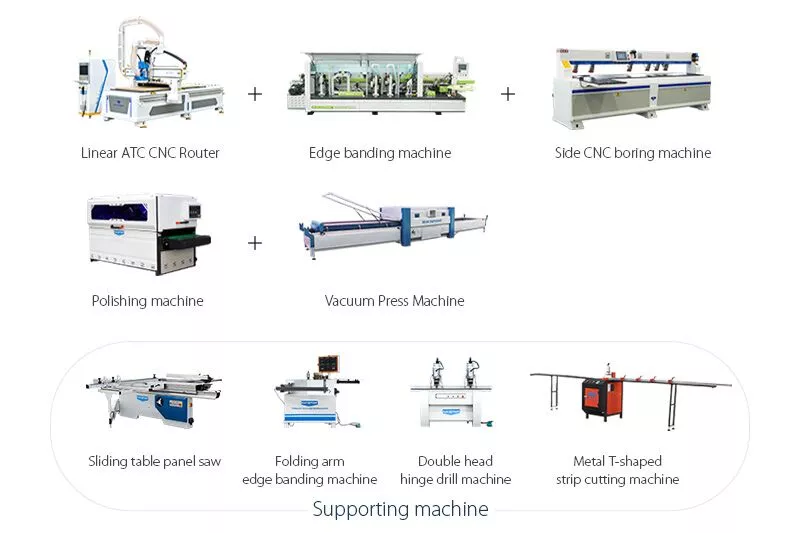

☆It consists of linear ATC CNC machine, edge banding machine, side drilling machine, polishing machine, laminating machine, penal saw, folding arm edge banding machine, double-spindle hinge drilling machine, and metal strip cutting machine. This solution can meet the needs of whole-house custom manufacturers with flexible machine combinations and versatile processes.

SMART FACTORY VIDEO

Features

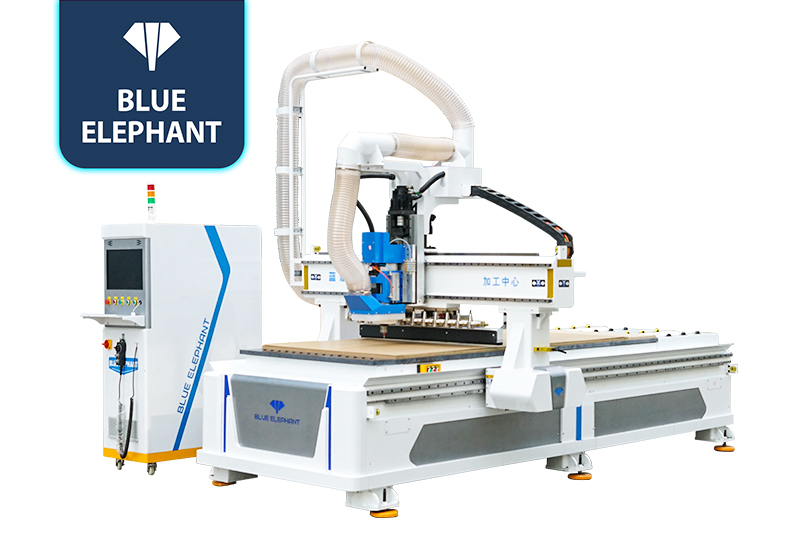

Linear ATC machining center:

Introduction: The linear ATC machining center can engrave the furniture, wooden doors, cabinets, tables, chairs and other wood workpieces. It is equipped with an independent tool magazine, and can change tools automatically in the course of processing without stopping the current work.

Features:

- It is suitable for complex and diversified production and processing work, such as drilling, cutting, side milling, beveling etc.

- All mechanical and electronic parts of this machining center adopt internationally famous brands.

- The automatic tool changer with 12 tools ensures fast tool changing and high efficiency.

- Strong software compatibility.

Edge banding machine:

Introduction: The edge banding machine is widely applied to panel furniture, customized furniture, cabinets, office furniture, wood furniture, tables & chairs, windows & doors, wood products and decorations. It is able to process a variety of panel materials, such as density fiberboard, ecological boards, composite boards, particle boards, plane wood boards, aluminum honeycomb panels etc.

Features:

- Functions: gluing and pasting → aligning head and end → rough trimming → fine trimming → edging → polishing.

- Gluing and pasting: the cylinder-controlled gluing switch (which adopts WSN cylinder and EASUN solenoid valve) ensures stable gluing amount and uniform thickness.

- Aligning head and end: it can cut the excess edge band at both ends of the sheet (WSM cylinder with 2 regulators and 1 pressure relief valve) for more stable air pressure and more stable flush end.

- Rough trimming: this machine can eliminate excess edge band with six-edge alloy plain cutter.

- Fine trimming: it is able to cut the excess edge band with six-edge R-shape cutter into round corners, gaining more beautiful appearance.

- Profiling tracking: the machine can trim the four corners to make them more smooth and not stinging, and the independently designed tracking action and airway design make the profiling more stable.

- Edging: the super-hard alloy R-shape cutter is able to slick the cracks on edge bands, making them more smooth.

- Polishing: the buffing wheel can polish the edges of the edge bands rapidly to make them more rounded and pretty.

Side drilling machine:

Introduction: The side drilling machine is designed for panel furniture and cabinets, such as wardrobes, closets. It is capable for the side drilling work of three-in-one side holes/wood pinholes/blind holes/fixed groove/straight slot/four invisible parts.

Features:

- With smart drilling, it has no need to pay attention to the panel size; and it can judge the drilling position by accurate positioning with laser canning.

- Customized limit switch, protects human safety.

- It can drill holes immediately after the panel is put on the machine, without swiping bar code, which is more quick and convenient.

- Free switching among multiple drilling modes is allowed to meet various processing requirements.

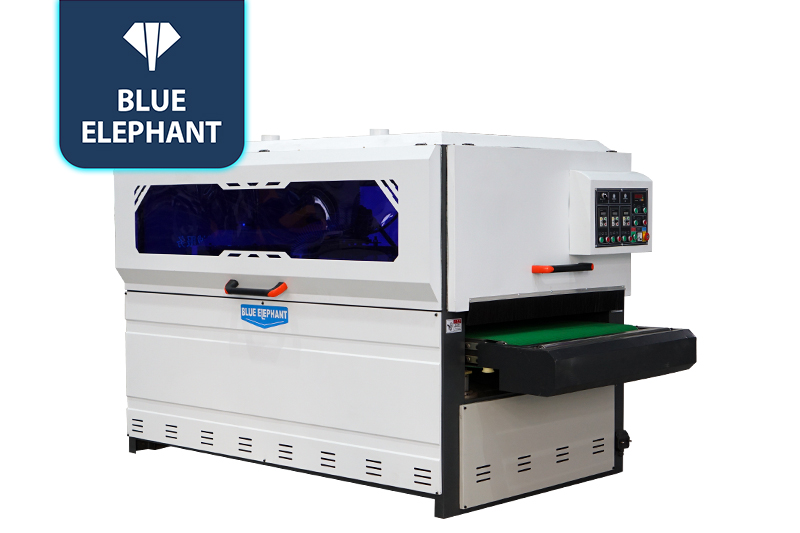

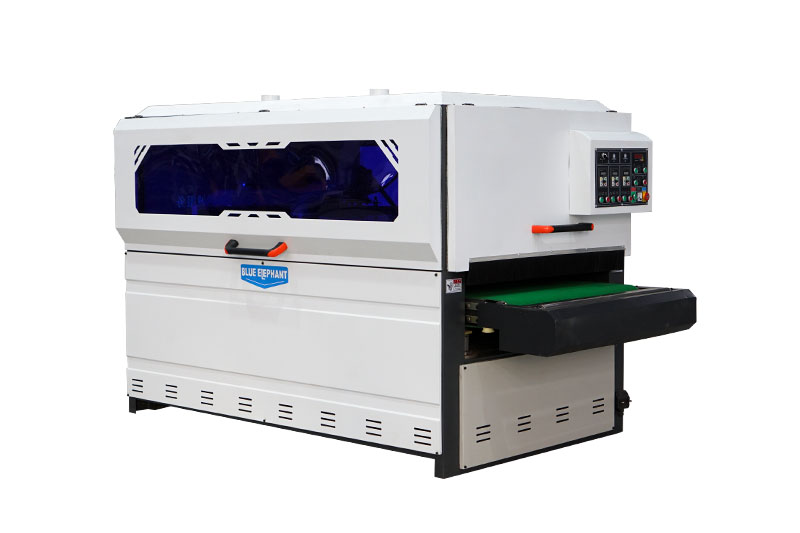

Polishing machine:

Introduction: The polishing machine is used for rough and fine sanding, buffing and polishing the side surface, anisotropic surface, plane and curve surface of straight, L-shaped wood boards and door panels of various materials, such as solid wood, density fiberboard, tinplate etc. It is the ideal equipment for anisotropic polishing processing for doors, windows, cabinets and other furniture.

Features:

- It is suitable for surface processing of wood products, mainly for work blank sanding and primer polishing of wood products.

- Frequency conversion speed regulation is adopted, so the speed can be freely adjusted to select the appropriate feeding speed to ensure the quality of the workpiece polishing.

- The abrasive roller consists of sisal brushes and gauze. Various combinations of gauze and brushes are available, and the gauze and brushes can be replaced separately to save costs.

Vacuum press machine:

Introduction: The vacuum press machine can paste various PVC films on furniture, cabinets, speakers, paint-free doors and other materials in three dimensions, and can be used for thermal printing film and single-sided solid wood veneer after the addition of silicone plate.

Features:

- Flexible switching between curved and straight edge banding mode is allowed without interference and misoperation, which is accurate and convenient.

- With a limit switch, the machine can be shut down automatically.

- It is capable for processing such materials as: PVC, wood veneer, melamine, plastic etc.

Precision saw:

Introduction: Precision saw is used for the longitudinal sectioning and cross-cutting work of various board materials, such as density fiberboard, particle boards, artificial boards, ABS boards, PVC boards, PMMA, solid wood panels and other panels with similar hardness.

Features:

- European guiding rule can avoid displacement and ensure precision of panel cutting.

- Movable worktable is made of extruded aluminum alloy with high strength and no deformation.

- Extended and enhanced machine body ensures the machine stability during working.

Curved and straight edge banding machine:

Introduction: The curved and straight edge banding machine is applicable for the banding work for straight and irregular edges of the panels.

Features:

- Flexible switching between curved and straight edge banding mode is allowed without interference and misoperation, which is accurate and convenient.

- With a limit switch, the machine can be shut down automatically.

- It is capable for processing such materials as: PVC, wood veneer, melamine, plastic etc.

Double-head hinge drill machine:

Introduction: This machine is mainly applied to the boring of furniture door hinges, such as cabinet doors, wardrobe doors, office and household furniture doors. It is able to adjust the boring position in both longitudinal and horizontal position in order to accommodate the boring requirements in a fast and convenient manner.

Features:

- The drill package design ensures small noise and durable use.

- A positioning baffle and an accurate scale are adopted, which can be adjusted based on work demands.

- Controlled by a foot switch, it is convenient and labor saving.

- Multiple functions, and it is adaptive to multiple types of drill heads.

Metal strip cutting machine:

Introduction: The metal strip cutting machine is mainly designed for new Chinese style door panel inlay, and it can cut metal strips off directly or cut continuously without breaking.

Features:

- One-touch start button switch.

- Foot pressing mode without hand pressing.

- Automatic pressing and cutting function.

- Save time, labor and cost.

- Precision alloy saw blade adopts hardening process, ensuring long service life.

- The saw teeth are isosceles and right-angled, and can cut accurately without error, and the saw blade is easy to replace.

- The extended pallet is convenient for continuous cutting and can be folded and disassembled easily.

Production Facility

Quality Control & Testing