Best Smart Factory Furniture Production Line in Luxembourg, Estonia, Brazil

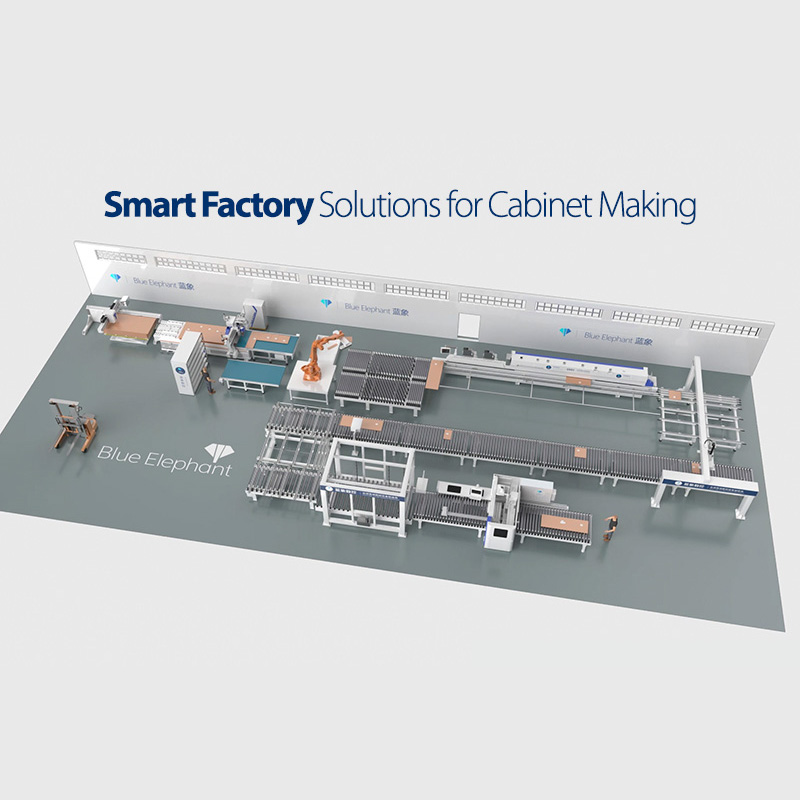

☆This high-end intelligent production line is consist of CNC cutting unit, edge banding rotary unit, CNC row drilling unit, and cache bin storage system. It can achieve visual, automatic, and intelligent production. Moreover, the whole process is traceable.

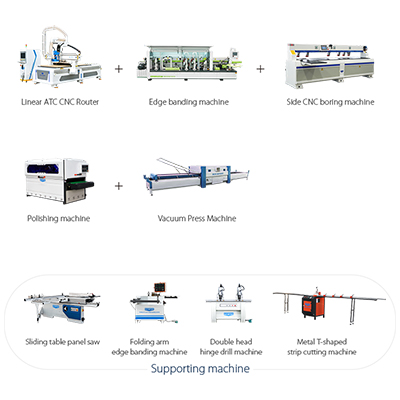

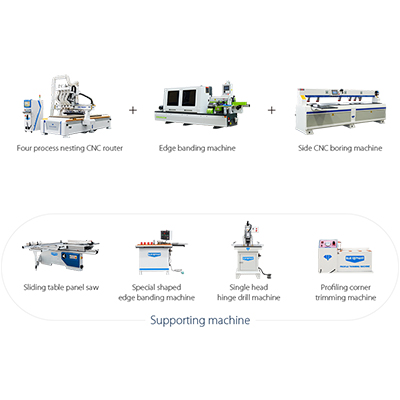

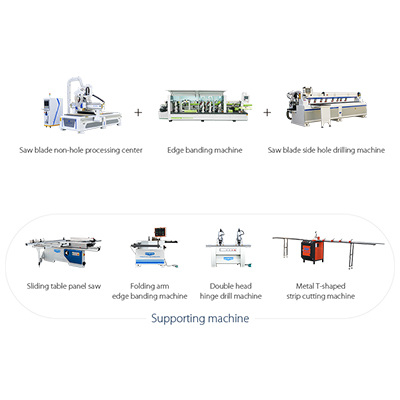

Intelligent factory furniture production line solution :

Number of Intelligent Connection Line Employee Required:

| Connection Line Solution |

Staff Number Required |

Total Employees |

| CNC Cutting Unit |

1 |

4 |

| Edge Banding Rotary Unit |

1 |

| CNC Row Drilling Unit |

1 |

| Sorting & Packing |

1 |

Connection Line Advantages:

- With no skilled workers needed online, it greatly reduces labor cost and management cost, and ensures no errors in production.

- Without shutdown of any machine, it may reach the maximum theoretical production efficiency, which is at least 25% higher than a single machine.

- Having no constraint by manual production on taking large or rush orders, the machine can operate without interruption in two or three shifts to expand production and sales with no worries, which greatly improves the rate on investment of lands, factory buildings and equipment.

- With flexible production on multiple orders, it automatically collects leftover pieces for storage and recycling, thus improves utilization ratio of the plates.

- It supplements orders quickly, has strong strain capacity on production, rapidly pushes production of orders in the same batch, shortens production cycle, quickly delivers products to clients with high quality and high satisfaction.

- It reduces plates damaging rate by 75%.

- With efficient coordination of software and hardware, it achieves visual, automatic, intelligent production,and the whole process is traceable.

- Connection line circulation is efficient and precise, reduces plates stock, decreases logistics occupancy area, and improves productivity and capital turnover.

- By reducing the constraints of labor, management, and efficiency on business development , the machines provides the competitive advantages of cost, flexible production and quick and high quality delivery that are not available in the same industry, and takes the lead in the development of the industry.

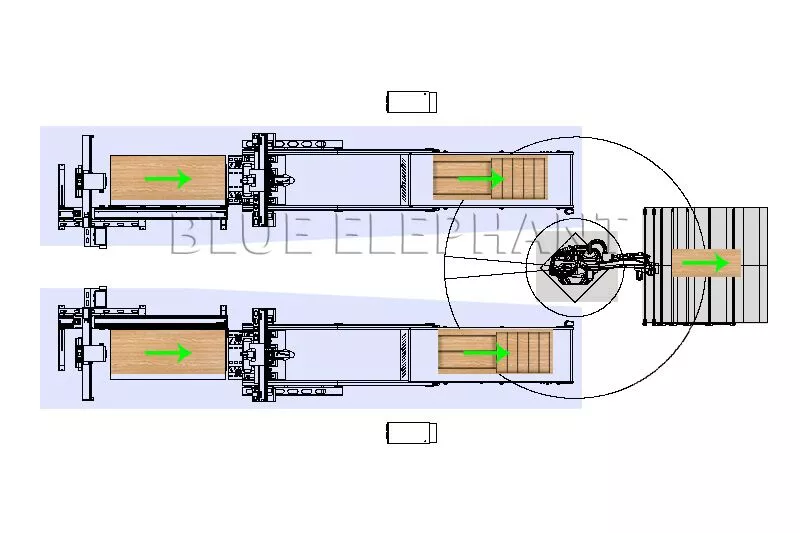

Part 1: Cutting Unit:

Forklift delivering plates to elevator → Labeling machine grabbing and auto labeling plates → Cutting machine drilling, grooving and cutting plates → Robot grabbing plates and delivering plates to translation power live-roller gear → plates entering into cache bin and waiting to be delivered to edge banding unit

Equipment List:

| Equipment Name |

Unit |

Quantity |

Employees |

| Automatic labeling machine |

Set |

2 |

1 |

| CNC cutting machine |

Set |

2 |

| Blanking platform |

Set |

2 |

| Power convey roller |

Set |

1 |

| Robot |

Set |

1 |

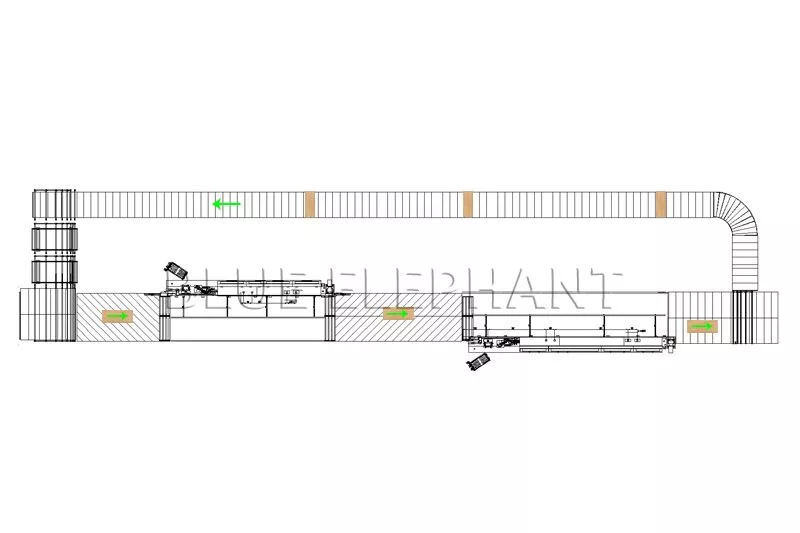

Part 2: Edge Banding Rotary Line

Plates are delivered by power roller to edge banding machine → The first edge banding machine sealing the first edge → The second edge banding machine sealing the third edge → Plates rotating by 90°and the edge banding machines sealing the second & fourth edge → After edge banding, plates are transferred into cache bin and waited to be delivered to row drilling unit

Equipment List:

| Equipment Name |

Unit |

Quantity |

Employees |

| Edge banding machine double-row oblique roller with left and right connection |

Set |

2 |

1 |

| Forward edge banding machine |

Set |

1 |

| Reverse edge banding machine |

Set |

1 |

| 90° power steering roller |

Set |

1 |

| High-speed camera |

Set |

2 |

| Translation belt conveyor |

Set |

3 |

| Translation power convey table |

Set |

5 |

| Single-row oblique roller |

Set |

1 |

| Power convey roller |

Set |

11 |

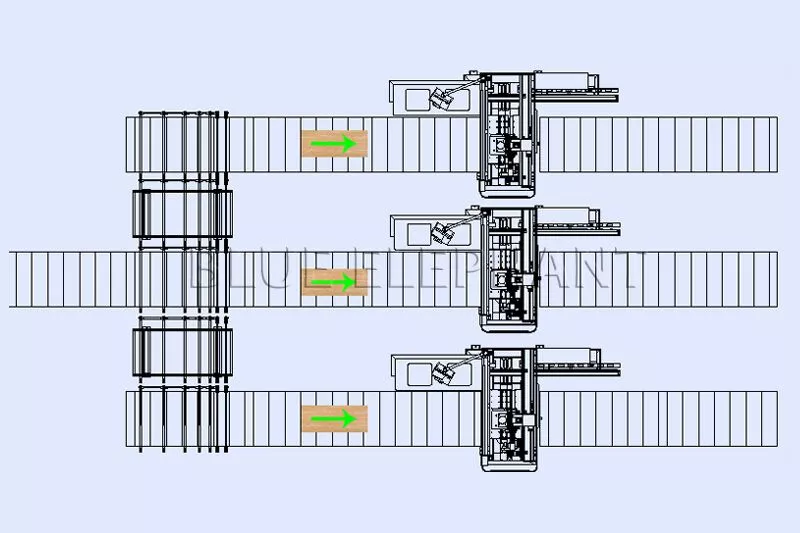

Part 3: Drilling Unit

After edge banding, plates entering into six-side drilling machine → After drilling, plates are outputted under “front in, front out” or “front in, back out” mode → Plates entering into cache bin for sorting and packaging

Equipment List:

| Device name |

Unit |

Quantity |

Employees |

| Translation power convey gear |

Set |

Depend on actual connection line |

1 |

| Translation belt conveyor |

Set |

| High-speed camera |

Set |

| Six-side drilling machine |

Set |

| Power convey roller |

Set |

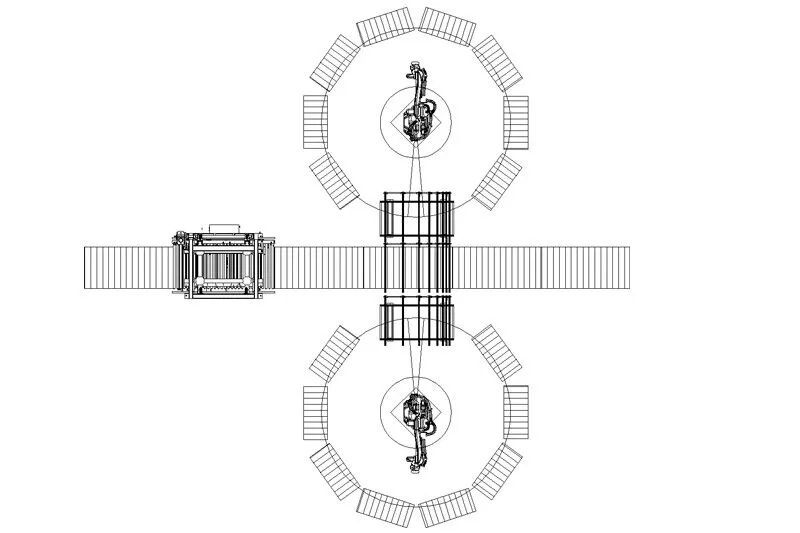

Part 4: Sorting Unit

Equipment List:

| Device name |

Unit |

Quantity |

Employees |

| Vertical cache bin |

Set |

1 |

1 |

| High-speed camera |

Set |

1 |

| Translation belt conveyor |

Set |

2 |

| Translation power convey roller |

Set |

1 |

| Intelligent sorting robot |

Set |

2 |

| Power convey roller |

Set |

3 |

| Manipulator clamp with suction cup |

Set |

2 |

| Manipulator feed bin |

Set |

12 |

Production Facility

Quality Control & Testing